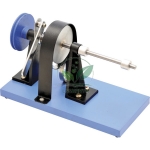

Compressor

Product Code : SCL-PL-11427

Engineered for high-duty cycle pneumatic experiments, this

300 W Laboratory Compressor provides a stable air supply for air tracks,

hovercraft models, and fluid dynamics apparatus. Adhering to CE and ISO safety

protocols, it is designed for Secondary and Vocational TVET environments. The

unit features integrated circuit protection and a 2-meter reinforced hose to

ensure operational continuity in high-use university-prep laboratories.

Technical Specifications

|

Tender Specification |

OEM Technical Detail |

|

Material Grade |

Impact-Resistant Technical Polymer / Reinforced Alloy

Housing |

|

Dimensions |

Ø20 x h30 cm |

|

Motor Power |

300 W (Calibrated for high-torque laboratory startup) |

|

Hose Configuration |

2 m reinforced high-pressure flexible tubing |

|

Electrical Safety |

Top-mounted socket with integrated accessible fuse |

Key Pedagogical Outcomes (Bloom’s Taxonomy)

- Constant

300 W Output: Allows students to analyze uniform linear motion

on air tracks by providing a frictionless environment, supporting

Kinematics Module 2.1.

- Integrated

Top-Mounted Safety Fuse: Students apply electrical safety

protocols during experimental setup, preventing circuit overloads during

multi-apparatus testing.

- Extended

2m High-Pressure Hose: Enables students to design and construct

expansive pneumatic circuits and fluid power demonstrations without

proximity constraints to the power source.

International Logistics & Compliance

This school instrument is secured in export-grade seaworthy

crating (ISPM-15 compliant) to protect the internal motor alignment and

structural integrity of the Ø20x30 cm housing during global transit.

Procurement documentation includes the Manufacturer’s Authorization Form (MAF),

optional IQ/OQ/PQ Certification for institutional tenders, and technical

manuals in English. The ruggedized hardware features a tropicalized design,

laboratory-tested for operational durability in high-humidity environments (up

to 45°C / 90% Humidity), preventing the motor overheating and coil oxidation

common in non-OEM grade alternatives.